Examples of mass timber products

A wide range of mass timber products are manufactured right here in B.C. You can explore these mass timber products in more depth on our products pages.

We hear about mass timber more and more these days, but what exactly is mass timber and how are these products made?

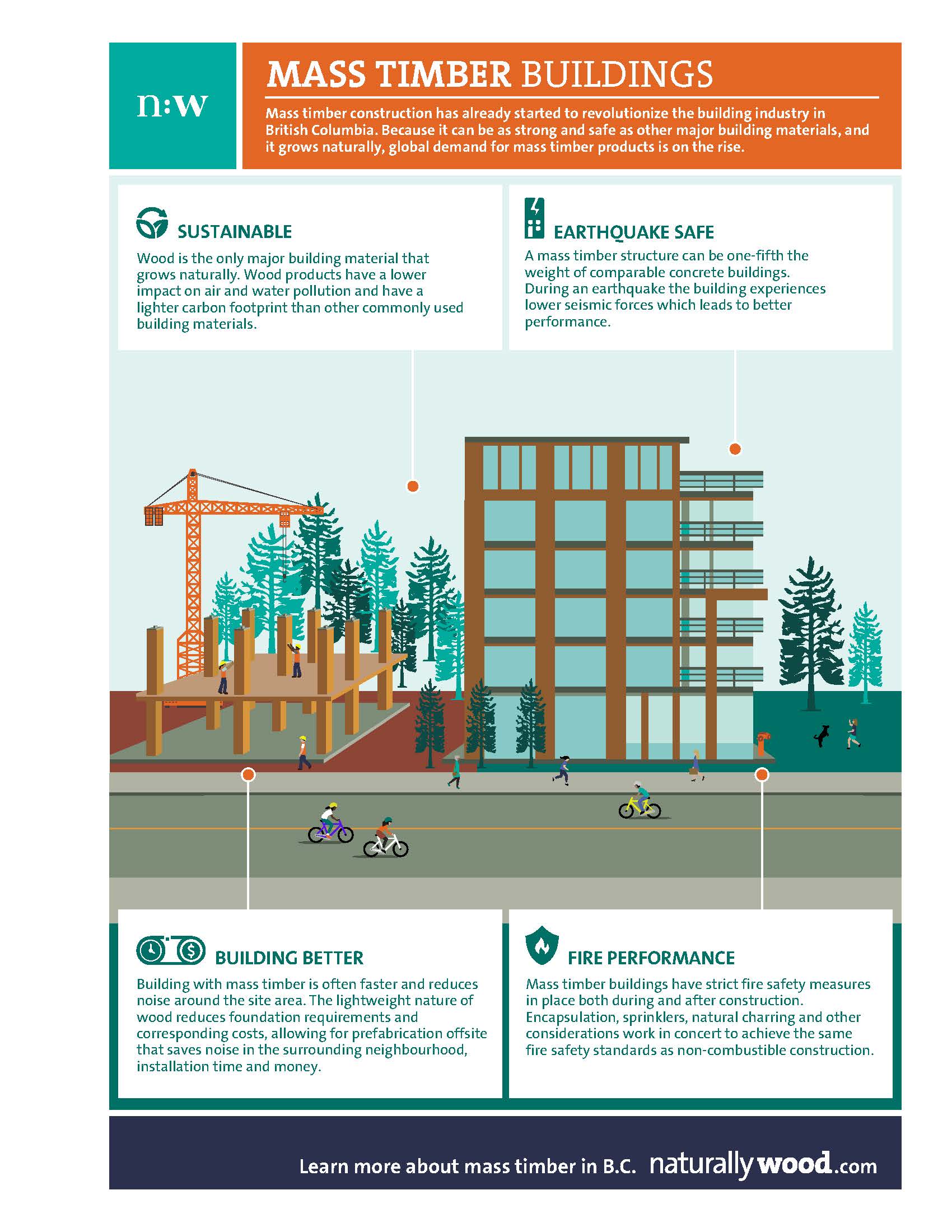

Mass timber construction, in contrast to light-frame wood construction, is built using a category of engineered wood products. These products are typically made of large, solid wood panels, columns or beams—often manufactured off-site—and are used for load-bearing wall, floor, and roof construction. Mass timber products are thick, compressed layers of wood, creating strong, structural load-bearing elements that can be constructed into panelized components. Mass timber products are engineered for high strength ratings like concrete and steel but are significantly lighter in weight. They are typically formed through lamination, fasteners, or adhesives. Mass timber can complement light-frame and hybrid options and is an environmentally friendly substitute for carbon-intensive materials and building systems.

Manufacturing of laminated veneer lumber (LVL), one of seven different mass timber products made in B.C. | Photo credit: Brudder Productions

A wide range of mass timber products are manufactured right here in B.C. You can explore these mass timber products in more depth on our products pages.

Mass timber is on the rise throughout B.C. Here are some diverse examples of how each of the six regions of B.C. are making innovative use of this homegrown climate-smart building product.

The Prophet River Multiplex, located along the Alaska Highway south of Fort Nelson, is truly a vital community hub for the region providing administrative facilities, council chambers, a health centre, an Elders’ lounge, and a community centre for the Prophet River First Nation.

A fully glazed atrium extends the entire length of the building showcasing the facility’s mass timber structure. The ample glazing fills the interior with abundant natural light during the day and gives the exterior an inviting auburn glow at night.

Photo credit: Martin Knowles

The Energy House at Northern Lights College is a multi-use facility that demonstrates clean energy technology and enlightens students and visitors on the efficiency, effectiveness and beauty of wood products. The facility is the focal point of the school’s Centre of Excellence that provides training in clean energy technology, and it is located in Dawson Creek where the winter months dip to minus 40 degrees celsius making energy efficiency a must. Showcasing the warmth and beauty of exposed glulam post-and-beam construction and Douglas-fir decking, the project contributed to the region’s economy, sourcing workers and products locally.

Photo courtesy of Northern Lights College

When its 44-year-old ice arena was condemned due to safety concerns, the construction of the Upper Skeena Recreation Centre, built of mass timber and wood-frame construction, delivered efficiency, innovation, and hope to this remote northern region. Drawing on local expertise and materials, the highly collaborative project brought this small close-knit community closer together—while providing jobs and a boost to the local economy. Choosing wood meant construction could continue through the cold winter months, unlike steel welding—a method hampered in below-freezing temperatures. This all-wood solution delivers structural performance and ease of installation, with the added benefits of aesthetic warmth, natural insulation, carbon sequestration, and locally sourced materials and labour.

Photo credit: Ema Peter Photography courtesy of Hemsworth Architecture

The Nadleh Whut’enne Yah Administration and Cultural Building is a critical community hub for the Nadleh Whut’en First Nation, whose territory is near the base of Mount Fraser, in the geographic centre of B.C. Along with hosting council meetings, it serves as a health centre, offices, community kitchen, learning centre, gymnasium, outdoor amphitheatre, and cultural and historical display. Central to its design is the two circular structures that serve as the lobby and council chambers—dramatic rooms with vaulted glulam beam roofs that are clad in western red cedar.

Photo credit: Martin Knowles courtesy of Evans Architecture | Joe Y. Wai

Featuring everything from CLT and glulam to LVL and PSL, the Wood Innovation and Design Centre (WIDC)—built using local B.C.-based products and expertise—shows what’s possible using mass timber construction and tall wood design. As a demonstration project, WIDC not only showcases a wide range of locally sourced products and species but serves as a repeatable and expandable template for constructing future tall wood buildings of different sizes and functions. The building features five home-grown sustainably-sourced wood species—including Douglas-fir, western red cedar, hemlock, pine and spruce—and were all sustainably harvested from B..C forests. Traditional wood products like dimension lumber and stained-red plywood panels were also used in various unique ways.

Photo credit: Ema Peter Photography courtesy of MGA | Michael Green Architecture

Located near Hanceville, the Yunesit’in Health Centre, with its striking design, was developed by the Yunesit’in people of British Columbia’s Cariboo Chilcotin region. The facility’s architecture is a contemporary expression of the traditional Yunesit’in house, embodying both the material qualities of the original buildings and the environmental values of the Yunesit’in people. Along with the use of mass timber—vertical glulam posts punctuating its design—the building features traditional light-frame construction using locally-sourced B.C. lumber and wood products. The result is a building as beautiful as it is practical.

Photo credit: Martin Knowles courtesy of David Nairne + Associates

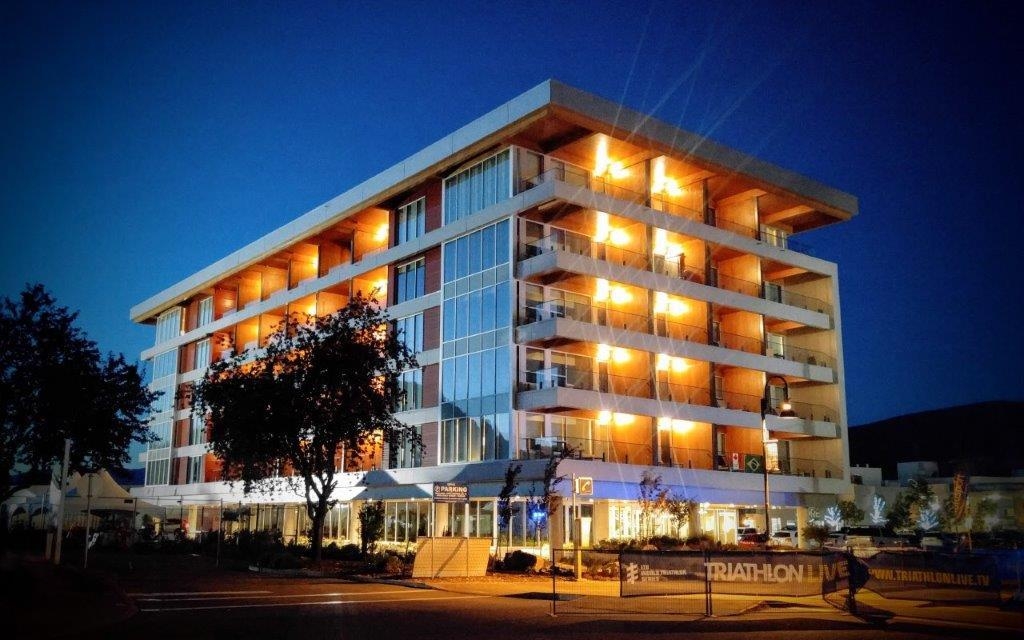

Situated on the south end of Okanagan Lake, an area popular with tourists and locals alike for its recreational activities, wineries, and fruit orchards; The West Wing, Penticton Lakeside Resort and Conference Centre is a six-storey, 70-unit hotel sets a new standard for the use of mass timber in commercial and hospitality projects. Giving visitors a truly made-in-B.C. experience, the hotel features an exposed timber structure—made of a Douglas-fir glulam post-and-beam frame with CLT floors, roof, shear walls, stairwells and stairs—envelops visitors with a sense of warmth and modern rusticity. Glulam was also used to build a dramatic nine-metre-high wall using a double lattice of beams to frame the windows.

Photo courtesy of Structurlam and HDR Architects

Featuring an abundance of locally sourced wood, the Okanagan College Jim Pattison Centre Of Excellence is a net-zero centre for sustainable building technologies and renewable energy conservation is a lesson itself in how to reduce our environmental impact using renewable materials and advanced construction techniques. Designed to be as much a lesson in itself as it is a place to learn, the building demonstrates to students firsthand made-in-B.C. sustainable mass timber building products and innovations. All structural wood used in the centre comes from local forests, including pine from Interior forests that have been impacted by the mountain pine beetle outbreak. The building is primarily a glulam post and beam structure, but also features a number of innovative components including timber-concrete composite wall panels with integrated heating and cooling pipes and steel-timber hybrid trusses.

Photo courtesy of CEI Architecture

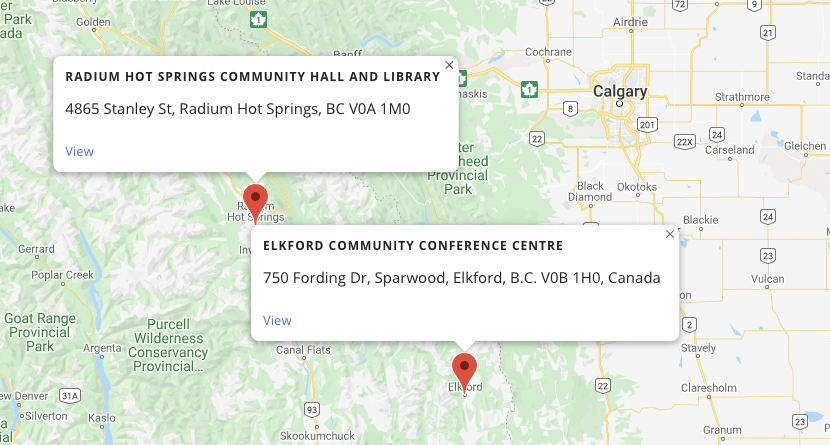

The Elkford Community Conference Centre is a cultural hub for the 3,000 residents of Elkford hosting an early childhood play school, recreational programs, conferences and community events. The facility showcases made-in-B.C. innovative wood construction including CLT shear wall panels, as high as 7.2 metres—the first time they had been used in a commercial application in North America. Glulam and LVL beams are supported on the CLT walls or perimeter columns. Structural insulated panels (SIP) used on the roof and walls give a substantial boost to the facility’s energy efficiency.

Photo credit: Henry Georgi

Nestled in a forested valley next to the Kootenay National Park, the Radium Hot Springs Community Hall and Library offers a vibrant central hub and point of pride for the Village of Radium Hot Springs. Showcasing wood construction completed by local workers, the community hall is one of the first public buildings in British Columbia to be built using dowel laminated timber (DLT). The resulting building is a centrepiece to the village and has helped revitalize community programming and events.

Photo credit: Dave Best courtesy of Urban Arts Architecture

Throughout B.C., there is an increasing use of wood in healthcare facilities. One example is the Nanaimo Regional General Hospital featuring a signature canopy design supported by diagonal Douglas-fir glulam struts that spring from asymmetrical concrete bases. The struts support horizontal Douglas-fir glulam beams, and a secondary structure of solid Douglas-fir purlins and decking. Exterior seating benches in the area of the entrance are also made from reclaimed Douglas-fir. The use of made-in-B.C. wood products reflects the region’s longstanding connection to nature and a sustainable forest sector.

Photo credit: Artez Photography courtesy of Stantec

More and more schools in B.C. are built with wood due to their environmental and health benefits while giving a boost to local forest-based economies. École Au coeur de l’île incorporates reclaimed wood into its design, as well as glulam and mass timber panels, topped off with a 3,000-square-metre timber roof. Interior spaces used exposed glulam beams and mass timber panels to form unique reading alcoves and multi-purpose spaces.

Photo credit: Derek Lepper Photography courtesy of McFarland Marceau Architects

The first in a series of innovative transit station designs to incorporate wood, Brentwood Town Centre Station is an iconic structure on Metro Vancouver’s Millennium Line, with its double-curved futuristic form levitating above Lougheed Highway. Its sleek, canoe-like design foreshadowed the thoroughly modern, state-of-the-art town centre rising above it. Two decades later, the exposed wood shows little to no weathering, a statement on the durability of mass timber construction. More station designs followed this precedent-setting project, incorporating mass timber or other wood products in various architecturally expressive shapes and forms.

Photo credit: Tae Ik Hwang

Towering above The University of British Columbia’s (UBC) Point Grey campus, this ground-breaking 18-storey student residence is one of the tallest contemporary mass-timber hybrid structures of its kind in the world. It is also a clear demonstration of the cutting-edge innovation and technology at work in B.C.’s wood products, engineering and architecture sectors. The hybrid steel-concrete and mass timber structure is built of Douglas-fir glulam and PSL columns that directly support 5-ply CLT floor panels.

Brock Commons Tallwood House mass timber structure reached new record-setting heights through the use of advanced prefabricated construction and design. This included virtual design and construction modelling (VDC)—technology used to visualize, analyze and make better, more collaborative decisions at each stage of the project. VDC enabled the team to test and troubleshoot various solutions, output designs directly to the mass-timber manufacturer for precise fabrication and meticulously plan the sequence and assembly of on-site construction.

Extensive attention was given to fire safety. A back-up water supply and emergency power supply ensures the sprinkler system will function even if the building loses its standard water and electrical supply. In a fire, the mass timber will cha on the outside, while retaining strength, slowing combustion and allowing time for occupants to evacuate the building.

Photo credit: KK Law

Interested in learning more about mass timber design and construction? Take your knowledge to the next level with these useful tools and resources.

Eligible local governments throughout BC are invited to become early adopters of mass-timber technology for...

Learn MoreBritish Columbia’s cutting‐edge wood architecture and design are featured in the newly released book, Naturally...

Learn MoreA rising number of municipalities, in all corners of the province, are turning to innovative mass timber construction and design....

Learn MoreDiscover more wood design, construction, and forestry thought leadership.

Mass timber construction for residential and commercial buildings is far from a new technology but

Learn MoreYou’re planning a building—you need financing, a design, a general contractor and, critically, insurance. But

Learn MoreBy Brad Doff Tallwood 1 at District 56 | Photo courtesy of Design Build

Learn More